Air dryers are essential tools in many industrial and commercial settings. They provide a cost-effective way to maintain healthy air quality levels for workers, customers, and other stakeholders.

In this article, well explore the vitality of desiccant air dryers and discuss the benefits they offer in terms of controlling humidity and creating a safe working environment. We’ll also look at how these machines work to ensure that your business is protected from moisture damage and pollution.

Finally, you will learn about emerging technologies being used in modern desiccant air dryers that make them more effective than ever before.

Introduction to Desiccant Air Dryers

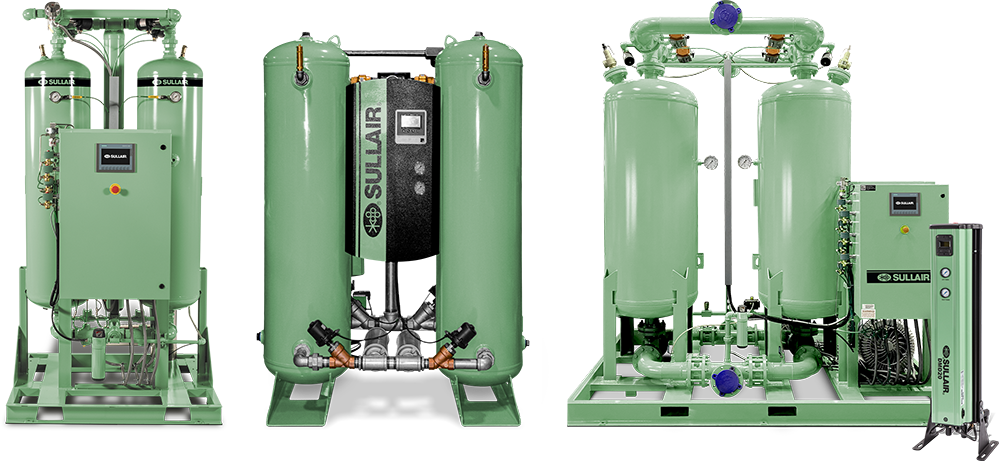

Source: america.sullair.com

Desiccant air dryers are a vital tool to reduce moisture in the air and create an optimal environment for many industrial processes. They have been used for decades in numerous industries, ranging from food processing to aerospace engineering.

Desiccant air dryers work by absorbing water vapor from the surrounding atmosphere using specialized desiccants – substances that can adsorb large amounts of moisture. This process creates a much drier environment that is necessary for many applications, such as preventing corrosion or avoiding contamination.

In addition, these systems are efficient, cost-effective and require minimal maintenance. This introduction will provide an overview of how desiccant air dryers work, their advantages over traditional drying solutions and other important considerations when making purchasing decisions.

Understanding the Benefits of Desiccant Air Dryers

Desiccant air dryers are an increasingly popular tool for controlling humidity in industrial and commercial settings. The benefits of using these machines to dry the air are numerous, from providing a more comfortable environment for employees to protecting delicate equipment.

Understanding how desiccant air dryers work is essential for those considering purchasing one, as well as understanding the many advantages that they offer. One of the most significant benefits offered by desiccant air drying systems is improved employee comfort. By removing moisture from the air, businesses can create a much more pleasant working environment while ensuring consistency throughout buildings of various sizes.

This equates to happier workers who are less prone to absenteeism due to health complaints or other issues caused by poor ventilation and high levels of humidity within their workplace.

Analyzing the Different Types of Desiccant Air Dryers

Source: gsadryer.com

When it comes to analyzing the different types of desiccant air dryers, there are several important factors to consider. Desiccant dryers use a chemical drying agent, typically silica gel or alumina, to remove moisture from the air.

The amount of time needed for drying depends on the type of material being dried and other conditions such as temperature and humidity levels in the environment. Furthermore, when choosing a desiccant air dryer it’s essential to consider its power consumption rate as well as any additional costs associated with maintenance and replacement parts.

Additionally, understanding which type of desiccant is most suitable depending on the application is critical for successful operation. Finally, you need to know how often you need to change out your desiccants in order to maintain optimal performance over time.

By taking into account all these details when making your decision you can ensure that you find an appropriate solution for your needs while optimizing cost efficiency at every step along the way.

Conclusion

Desiccant Air Dryers provide a powerful solution to the problem of moisture-laden air. Not only do they help maintain an ideal environment for many different types of materials and products, but their low energy consumption allows them to be used in any application.

The versatility of these devices makes them an invaluable addition to any facility looking to create a dry climate without sacrificing performance or incurring large costs. Desiccant Air Dryers are a reliable source of dry air that can help prevent costly accidents due to water damage and extend the life of many different types of equipment.