When it comes to industrial hoses, choosing the right one for the job can make all the difference. With a vast array of options available on the market today, its important to understand what makes each hose unique and how they can be used most effectively.

This guide will explore the ins and outs of industrial hoses so you can make an informed decision when selecting one for your project. From construction sites to factories, this guide has everything you need to know about industrial hoses so that your work is done safely and efficiently.

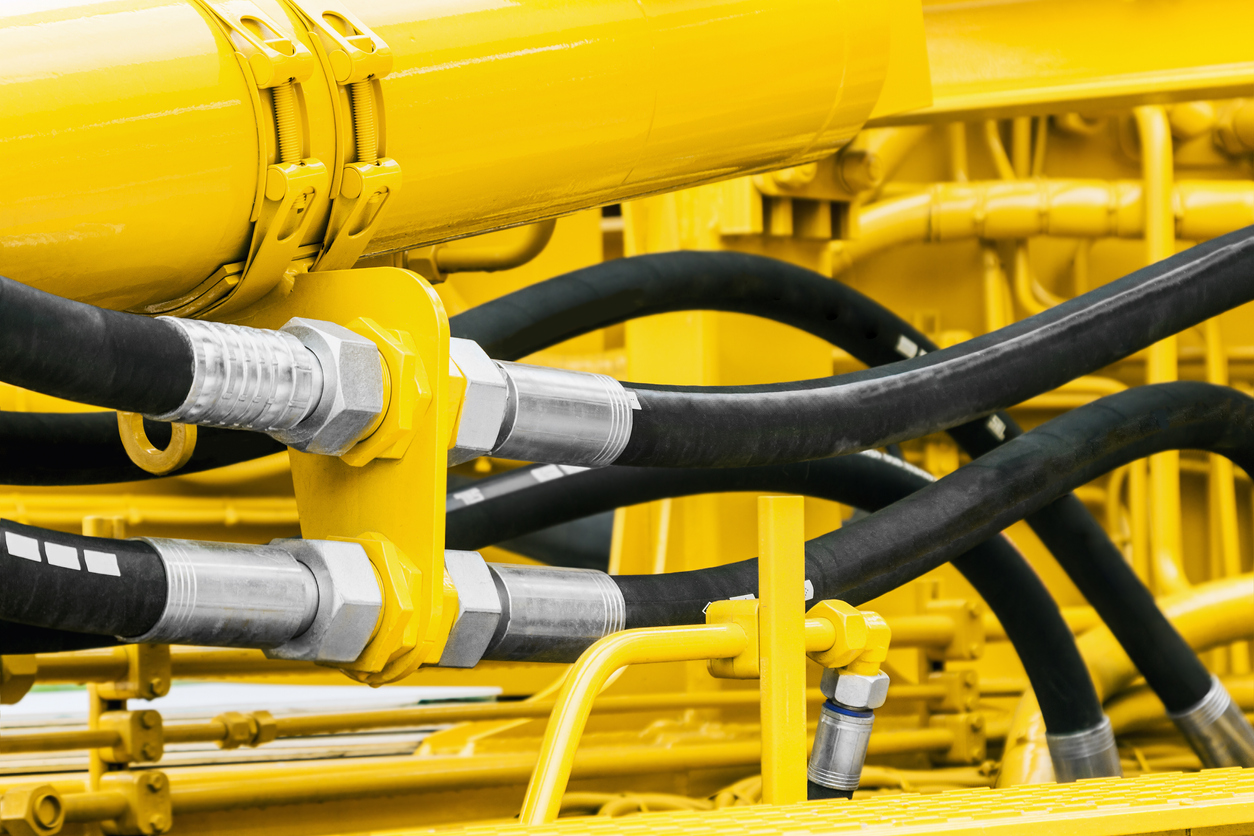

Types of Industrial Hoses and Their Uses

Source: tchindustries.com

Industrial hoses are an important tool for a variety of applications. In fact, many organizations rely on industrial hoses to accomplish tasks such as transferring air, water, chemicals and more. Understanding the different types of industrial hoses and their uses can make it easier to choose the right hose for each job. The most common type of industrial hose is made from rubber or PVC (polyvinyl chloride).

Rubber hoses are typically used in construction sites or other areas where durability is required since they resist abrasion and weathering. They may also be used with fittings that attach them to a range of tools or equipment. Other types of materials include thermoplastic elastomers which provide flexibility while maintaining strength and resistance against ozone, oil and heat; polyurethane which offers superior chemical compatibility; vinyl nitrile which has excellent petroleum-based oils and fuel compatibility; silicone which can withstand extreme temperatures; stainless steel braid reinforced clear tubing for high pressure transfer applications; PTFE (Polytetrafluoroethylene) that resists wear due to friction as well as corrosion from harsh chemicals or fluids; glass fibre reinforced plastic (GRP) fire retardant hose with durable outside covers designed specifically for aircraft refueling operations;

Kevlar covered hose offering greater abrasion resistance than traditional rubber hoses when exposed to sharp objects such as rocks/stones etc.; lay flat discharge water line designed specifically for fast draining purposes in agriculture & mining industry applications ; flexible metal interlocked hose suitable for steam transfer at very high temperatures up to 600 degrees Celsius among other things . Another consideration is choosing the right coupling system based on size requirements including end connections needed – threaded female swivel fitting , camlock couplings , union connectors , ground joint stem assemblies etc., temperature ratings whether its low temp plastics (-60°C), standard grade rubbers (-30°C/+70°C )or higher grade rubbers( -45°C/ +120°C) along with desired pressure rating depending on application needs like vacuum / negative pressure environments (<0 Bar), low pressures (<10 bar) medium pressures (32 bar ).

Ultimately, selecting the correct combination of these factors will ensure optimal performance without compromising safety standards making it easy task choosing right Industrial Hose every time!

Factors to Consider When Choosing the Right Hose for Your Application

When selecting the right hose for an application, there are a few factors to consider. First, it’s important to identify the environment in which the hose will be used. Different hoses are designed for different environments, and so it’s essential to choose one that is suited to the specific conditions. For example, if you need a hose that can withstand extreme temperatures or abrasive surfaces then you should look for something specifically designed with these features in mind. Second, consider what type of material your application requires from the industrial hose and select accordingly.

Generally speaking, rubber hoses provide excellent flexibility while stainless steel offers superior strength and durability – but other materials such as PVC may be better suited depending on your needs. Thirdly, think about pressure ratings; most commercial grade hoses have pressures ranging from 150 PSI (pounds per square inch) up to 690 PSI or more – again this depends on what kind of application you plan on using them for. Its also important not to exceed any specified maximum operating pressure rating as doing so could lead to premature failure or worse injury due to over-pressurization of the system.

Finally, when choosing an industrial hose you should always ensure that its length is appropriate for your project requirements – too short and it wont reach where needed; too long and unnecessary loss of liquid may occur through friction drag during operation resulting in decreased efficiency levels overall. In conclusion, when picking out a suitable industrial hose make sure that all these considerations are taken into account before making a decision – only by doing so can you guarantee both safety and functionality!

Maintenance Tips for Long-Term Use of an Industrial Hose

When it comes to maintaining industrial hoses for long-term use, regular inspections are key. Checking the condition of the hose regularly and replacing worn parts can save time and money in the long run. Additionally, you should always consider how your hose is being used before making a purchase – different types of hoses may require different levels of maintenance or care depending on their purpose.

When it comes to maintaining industrial hoses for long-term use, regular inspections are key. Checking the condition of the hose regularly and replacing worn parts can save time and money in the long run. Additionally, you should always consider how your hose is being used before making a purchase – different types of hoses may require different levels of maintenance or care depending on their purpose.

You should also take into account factors such as temperature and pressure when using your industrial hose. Ensuring that these parameters remain within acceptable ranges can help ensure optimal performance from your equipment over time. Its also important to properly store your hose when not in use; this could include storing it indoors or wrapping it with a protective cover if needed.

Finally, make sure to follow any manufacturer guidelines for proper cleaning and maintenance – this will help keep your equipment running at its best for longer periods of time!