Are you considering investing in laser equipment? From laser cutters to engravers, there are a wide variety of tools that can help you get the job done. But what type of machine should you choose?

This guide will provide an overview of the different types of laser equipment available and how they work, so that you can make an informed decision about which one is best for your needs.

1. Introduction to Laser Cutting and Engraving Equipment

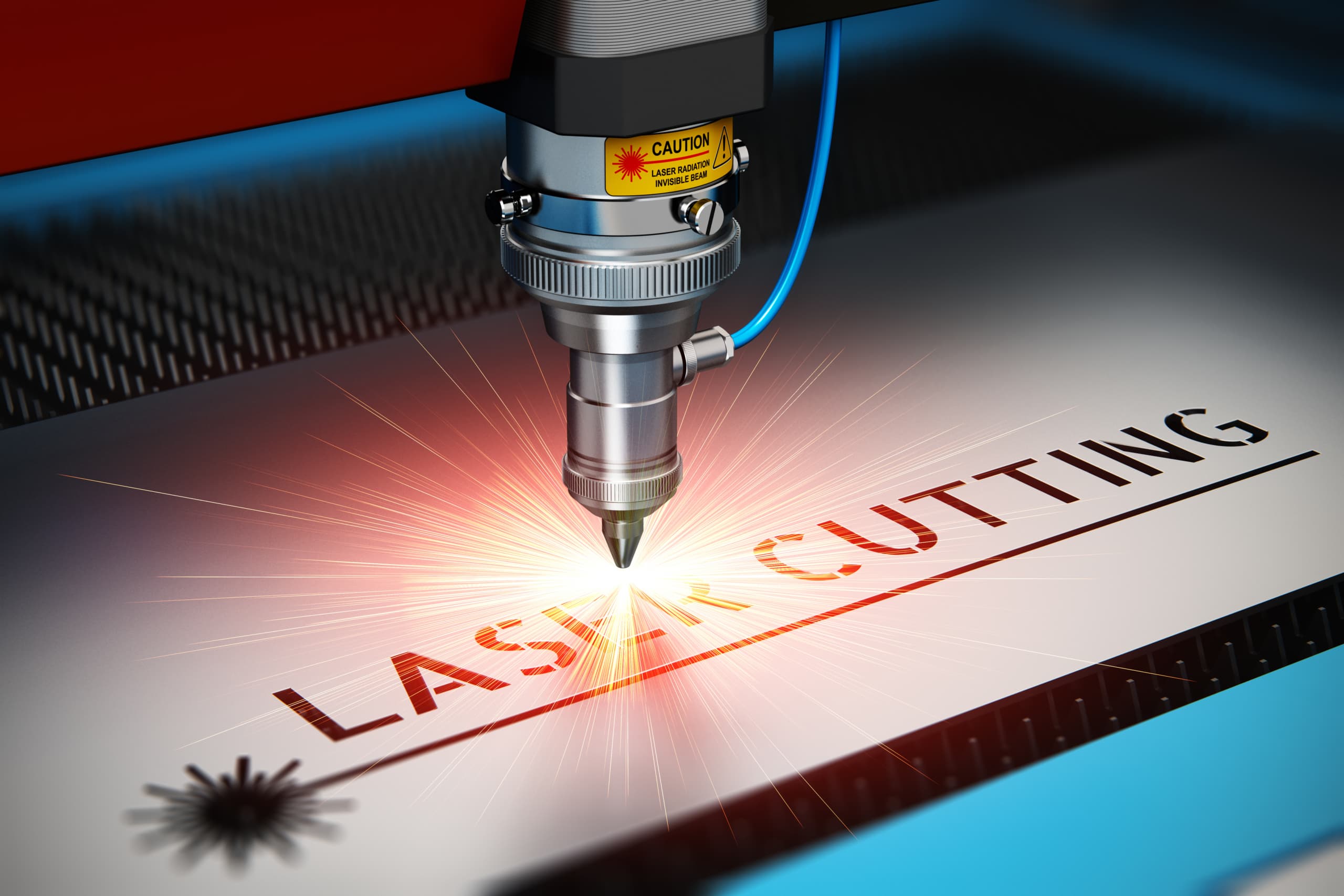

Laser cutting and engraving equipment is a technology that has revolutionized manufacturing processes across the world. From creating intricate designs on materials to marking parts for identification purposes, laser etching machines have changed the way we work with raw materials. This article will provide an introduction into the different types of lasers used in these applications, as well as some tips for using them correctly and safely.

Laser cutting and engraving equipment is a technology that has revolutionized manufacturing processes across the world. From creating intricate designs on materials to marking parts for identification purposes, laser etching machines have changed the way we work with raw materials. This article will provide an introduction into the different types of lasers used in these applications, as well as some tips for using them correctly and safely.

One of the most popular types of laser machines is CO2 lasers which are generally used for cutting or engraving materials like wood, plastic, metal and glass. They use a beam of infrared light to create precise patterns on objects quickly and accurately without requiring excessive heat or pressure during operation. These lasers can be found in many industrial settings where they are often employed to cut thick layers of material or etch intricate details onto components such as circuit boards.

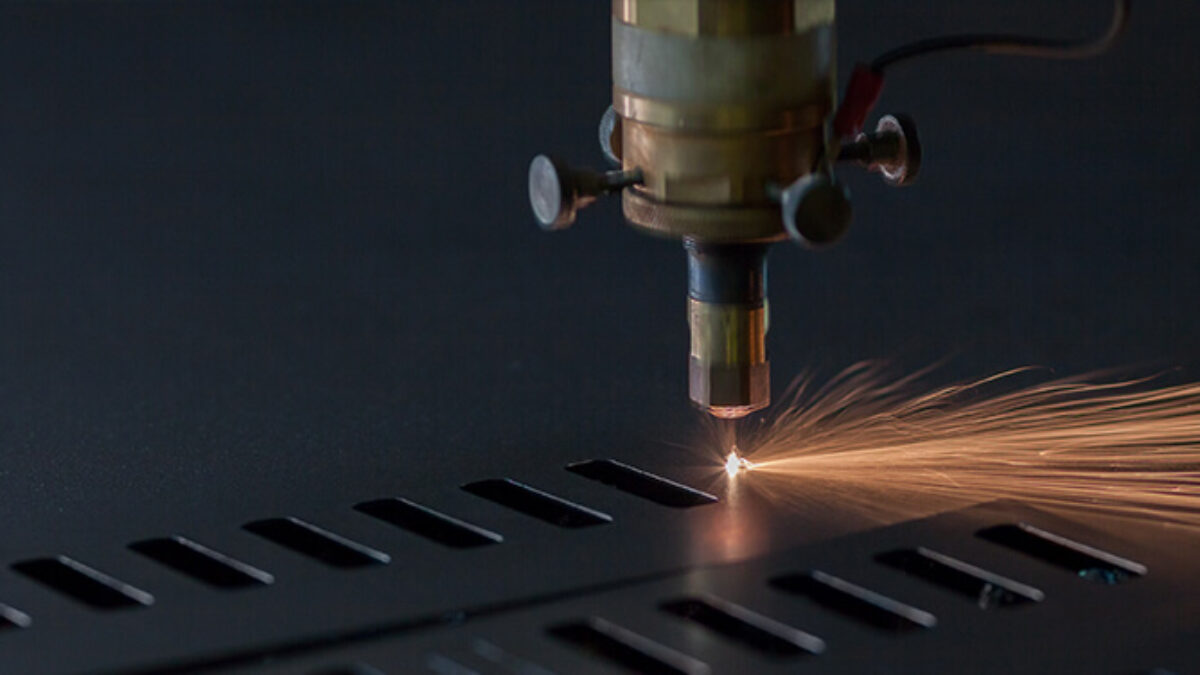

Fiber Laser systems are also becoming more widely used due to their higher power output compared to other types of lasers, making them ideal for more demanding jobs such as cutting thicker metals like stainless steel or titanium alloys at high speed while still maintaining accuracy levels needed by manufacturers today. While fiber laser systems may require a bit more maintenance than CO2 models they are worth it when considering the increased performance capability offered by this type of machine over its counterparts.

Finally YAG Lasers use short pulses that provide energy necessary for surface marking applications such as identifying products with serial numbers or logos without damaging underlying structures beneath the object’s surface layer – something not possible with either CO2 or Fiber Lasers due their higher power outputs which could damage delicate components underneath if operated incorrectly.

With so many varied uses and benefits from each type it can be difficult to know exactly what you need but hopefully this guide has provided you with enough information about each one so that you can make an informed decision when selecting your next piece of Laser Cutting and Engraving Equipment!

2. Overview of the Different Types of Lasers Used for Cutting and Engraving

Laser cutting and engraving is a rapidly growing industry, with ever-evolving technology. In order to get the most out of your laser equipment, it’s important to understand the different types of lasers available and their uses. This section will provide an overview of the main categories of lasers used for cutting and engraving: CO2 Lasers, Fiber Lasers, YAG Lasers, and Diode Lasers. CO2 lasers are among the oldest type of laser used in industrial applications such as cutting and engraving; they use carbon dioxide gas as their medium rather than solid-state materials like fiber or diode lasers.

Laser cutting and engraving is a rapidly growing industry, with ever-evolving technology. In order to get the most out of your laser equipment, it’s important to understand the different types of lasers available and their uses. This section will provide an overview of the main categories of lasers used for cutting and engraving: CO2 Lasers, Fiber Lasers, YAG Lasers, and Diode Lasers. CO2 lasers are among the oldest type of laser used in industrial applications such as cutting and engraving; they use carbon dioxide gas as their medium rather than solid-state materials like fiber or diode lasers.

They have been around since 1967 but remain popular due to their high power output (upwards of 200W) which makes them suitable for thicker material cuts or deeper engravings. The beam can be focused using mirrors which allows for greater precision when working on detailed projects. Fiber lasers are made from optical fibers doped with rare earth elements such as ytterbium or erbium that amplify light pulses through stimulated emission resulting in a powerful beam capable of producing smooth edges on even reflective materials like stainless steel or aluminum alloys without changing coloration during operation due to heat buildup from friction with air particles, making them ideal for marking purposes.

These lasers typically operate at lower wattages compared to other types (usually between 10W – 100W). YAG (yttrium aluminum garnet) Lasers are also known as solid-state pulsed Ruby / Nd: YAG lasers; they use crystals containing neodymium ions that emit light when pumped by flash lamps powered by electrical energy instead of gases like CO2 or chemical reactions unlike diode systems do so they require less maintenance while operating at higher powers than other types which make them perfect for deep etching applications requiring higher resolution detail work such as medical instruments manufacturing where accuracy is essential.

Lastly, Diode Laser systems consisting usually low wattage (<10W) semiconductor components similar to those found in consumer electronics products offer unparalleled portability allowing users great flexibility when working on any given project without having worry about bulky machines taking much space nor needing constant maintenance/calibration checks thanks its low complexity design compared against other more complex models mentioned above; however this comes at cost since these modules lack versatility when dealing with thicker materials although still offering outstanding results over finer details tasks making them ideal choice small scale operations involving thin metallic media sheets looking produce intricate patterns quickly effectively yet affordably .

3. Advantages and Disadvantages of Using Lasers in Manufacturing

Lasers have revolutionized the manufacturing industry, with their precision and speed providing significant advantages over traditional methods. The ability to precisely cut materials with lasers has made them a popular choice in many industrial settings, from laser cutting machines that rapidly cut through steel and other metals to engravers that can add intricate details onto surfaces such as wood, glass or metal. However, there are still some disadvantages associated with using lasers for manufacturing purposes.

The primary advantage of using lasers for manufacturing is its accuracy. Lasers allow manufacturers to create precise cuts and designs without having to worry about inconsistencies in the results due to hand-held tools or machinery not being perfectly aligned. This makes it easier for companies to produce products of a consistent quality at high speeds while keeping costs low. Additionally, laser cutting also enables manufacturers to work on thinner materials than they could previously by providing greater control over the material’s thickness during processing.

However, one potential disadvantage of using lasers is their cost – since they require expensive equipment and can be dangerous if not properly handled, it may not make sense for certain types of businesses or operations where manual processes would suffice instead. Also, depending on how quickly you need your product produced or what type of materials you need cut into specific shapes and sizes – manual processes might be more suitable than relying on an automated laser system which can be slower in comparison when dealing with complex tasks requiring multiple steps or working with thicker materials like steel plates that require more power or time.

Finally, laser systems generate heat during operation which means additional cooling measures must be taken in order ensure proper performance levels dont get affected by overheating components .

4. The Cost-Benefit Analysis of Investing in Laser Cutters or Engravers

When it comes to investing in laser cutters or engravers, the first thing businesses should consider is the cost-benefit analysis. The initial investment for a laser machine can be expensive and there are ongoing costs associated with maintenance and electricity. Therefore, performing an analysis of the potential return on investment (ROI) is essential. Businesses need to decide whether they plan to use their device frequently or just occasionally so that they can make sure they’re getting value from their purchase.

When it comes to investing in laser cutters or engravers, the first thing businesses should consider is the cost-benefit analysis. The initial investment for a laser machine can be expensive and there are ongoing costs associated with maintenance and electricity. Therefore, performing an analysis of the potential return on investment (ROI) is essential. Businesses need to decide whether they plan to use their device frequently or just occasionally so that they can make sure they’re getting value from their purchase.

Additionally, businesses should also factor in how quickly production throughput needs to occur when making purchasing decisions as some machines may be faster than others depending on its purpose. Finally, businesses should look into any special features available with different devices such as automatic shutoff or safety systems that could add more value over time when using their device frequently.

Investing in a good quality machine will provide longevity that could potentially pay off in terms of ROI while providing peace of mind knowing the device has been tested and approved by industry standards organizations like Underwriters Laboratories (UL). Taking all these things into consideration before making a decision ensures businesses have maximized their investments into laser cutting equipment while obtaining maximum benefit from them over time.