As the electronics industry continues to innovate, so too does how products are being produced. PCB assembly online technology has become an increasingly popular method of production for both small and large-scale operations. This article will explore the various benefits that this type of technology offers including cost savings, precision control, and scalability.

By using online technology to produce printed circuit boards (PCBs), businesses can reduce their costs while ensuring quality control throughout every step of the process. Additionally, this kind of technology is highly scalable and can be used for a wide range of projects from small prototyping efforts to high-volume production runs. Ultimately, PCB assembly online technology is revolutionizing how companies create and manufacture complex electronic components on a global scale.

Improved Efficiency and Cost Savings

The implementation of online PCB assembly technology offers several benefits for both small and large-scale production. One major benefit is improved efficiency and cost savings. With this technology, companies can save time by streamlining the manufacturing process and using automated tools to help with tasks like ordering components, uploading files, testing prototypes, etc. Moreover, the automation capabilities offered by these technologies reduce labor costs associated with manual processes such as soldering and reworking boards.

Additionally, since there are no setup or tooling costs required for online PCB assembly services it further reduces overall costs for businesses that need to produce circuit boards in small batches or on an ongoing basis. Finally, many providers offer flexible pricing options allowing customers to optimize their spending depending on their project needs without sacrificing quality or performance standards.

Increased Design Flexibility

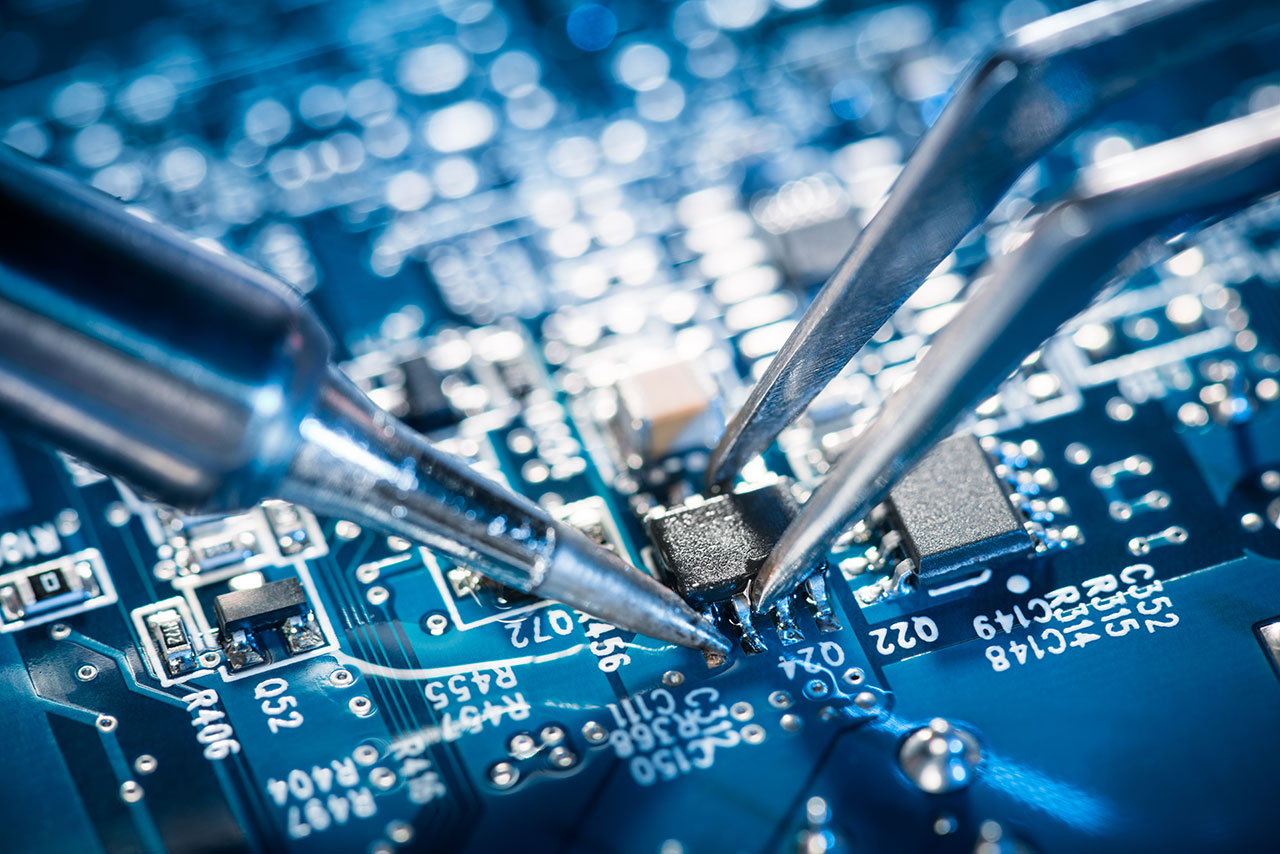

Source: newmatik.com

The use of online PCB assembly technology offers increased design flexibility for small and large-scale production. Designers now can make more intricate designs with a wider range of components, allowing them to create unique products which meet their specific needs.

This type of technology also saves time by streamlining the design process, making it easier to test and adjust different configurations until the desired results are achieved. Furthermore, online PCB assembly can be used for mass production as well as prototyping, giving designers even greater control over the end product. The combination of increased design flexibility combined with cost savings makes this an attractive solution for many businesses looking to manufacture on a budget without sacrificing quality or creativity.

Reduced Risk of Errors in Assembly Processes

The advent of online PCB assembly technology has revolutionized the way that small and large-scale production operates. This new form of manufacturing offers several benefits, one being reduced risk of errors during the assembly process. By streamlining the entire operation from design to order fulfillment, this cutting-edge technology ensures that each component is constructed with exact precision and accuracy.

Furthermore, detailed records are kept regarding all steps in the process which allows for traceability if any issues arise. As a result, businesses can rest assured knowing their products are produced efficiently with minimal mistakes or rework needed. The combination of accuracy and automation enables manufacturers to reduce labor costs while maintaining high-quality standards within their operations.

Enhanced Quality Control and Accountability

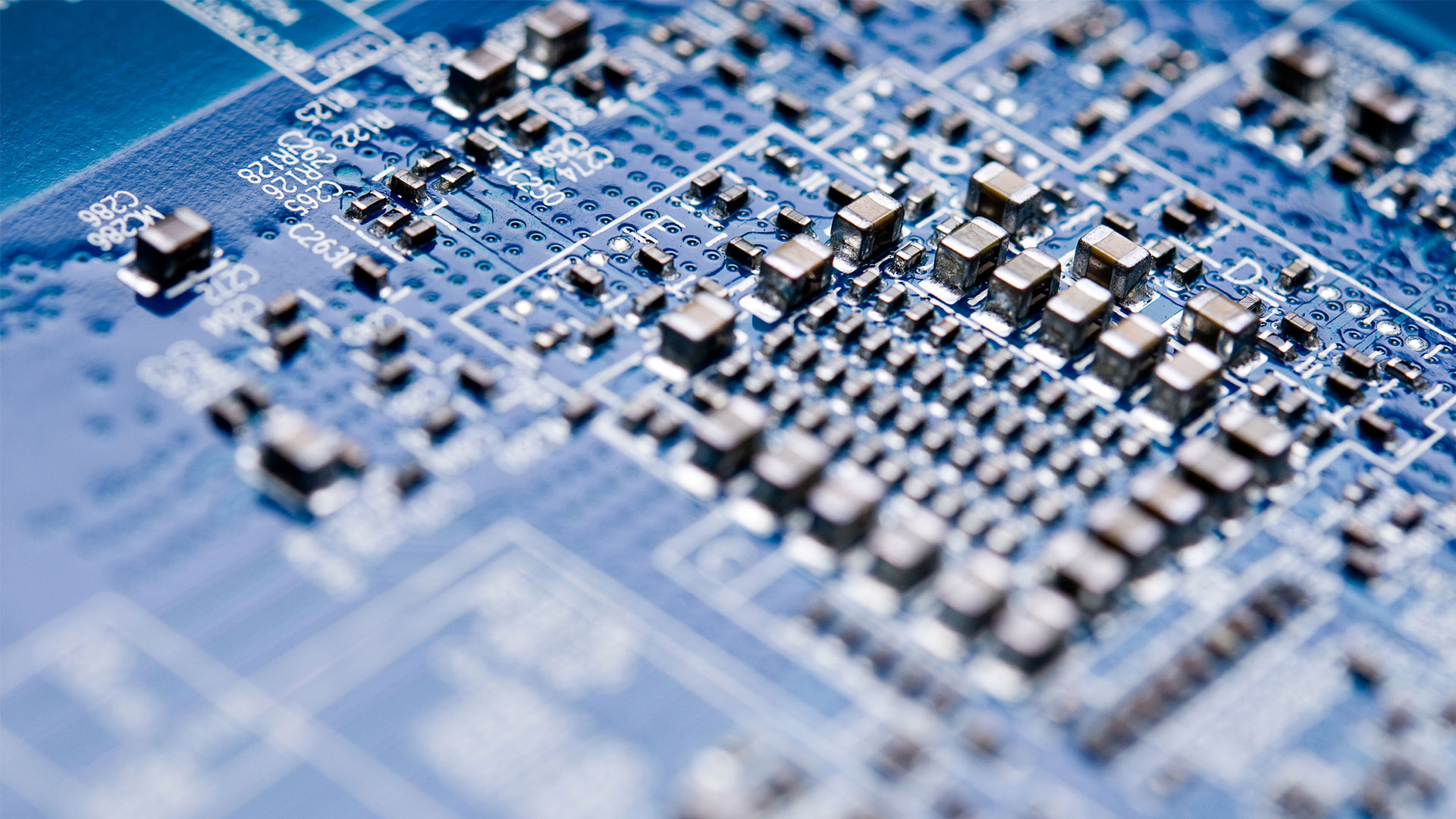

Source: sourceofasia.com

For small and large-scale production operations, PCB assembly online technology provides enhanced quality control and accountability. Through the use of automated systems that track each step in the process, manufacturers can be assured that no detail is overlooked. Additionally, any errors or issues during production can quickly be identified and corrected with minimal disruption to workflow.

In addition to providing a highly accurate product with fewer defects, this type of technology also ensures efficient tracking of materials used throughout the manufacturing process for improved inventory management. This helps to reduce costs associated with excess material usage while ensuring customers receive their orders on time. The combination of enhanced quality control and accountability offered by PCB assembly online technology makes it an ideal choice for businesses looking to improve their production capabilities while remaining cost-efficient.